Table of Contents

About

An Apple MacMini PowerPC G4, in spite of being released in 2005 and now a decades-old machine, is very useful due to the PowerPC representing a historical milestone in the crossroads between "retro" and "modern" computers.

Historically speaking, the Commodore Amiga 4000, end-of-line corporate machine was released in 1992, at which point Commodore figured that their Amiga design while bringing a lot of success, would have had to be redesigned in order to accommodate for faster machines and with more memory. At the time, Blizzard / Phase5 started to release accelerators or addon cards, advertising a huge speed increase for the common Amiga, from about  to a whupping

to a whupping  but with the only drawback that the accelerator was, in fact, using a PowerPC chip. The design was fairly unique, even in terms of software and the creators figured that the machine could run two kernels at the same time, one of them for the m68k Amiga and the other for PowerPC. To the user, the context switching between them was made seamless so the user could run an m68k application and a PowerPC application on the desktop a the same time, the two different CPUs running at the same time.

but with the only drawback that the accelerator was, in fact, using a PowerPC chip. The design was fairly unique, even in terms of software and the creators figured that the machine could run two kernels at the same time, one of them for the m68k Amiga and the other for PowerPC. To the user, the context switching between them was made seamless so the user could run an m68k application and a PowerPC application on the desktop a the same time, the two different CPUs running at the same time.

Commodore eventually went bankrupt and was unable to hold the pace but the common idea to the history and Apple computers is that the PowerPC was seen at the time as the next-up big breakthrough processor that all computers would be fitted with. This turned out to be false later and Intel quickly stepped up the game with regular PCs, developing very fast a series of CPUs, rushing through the Pentium series and then ending up with the core processors that even Apple Macintoshes are fitted with.

In any case, this leaves the MacMini PowerPC G4 perhaps the most affordable retro-computers carrying a PPC of the last generation (only G5 ensued and only in limited quantities before Apple switched to Intel). The usage for such a machine varies from writing code that runs on PowerPCs, running software that is outdated, running older games that only run on PowerPCs, studying the PowerPC itself or, lastly, running MorphOS, an evolutionary branch of the Commodore Amiga based solely on the PowerPC.

Opening Up the Case

Opening the case is a pain making one wonder why they did not simply just use four screws to hold the case together because it just might have been more cost-efficient. Instead, the case consists in two parts, a bottom and a top part that are just snapped together in place and held like that by a series of plastic teeth - and oh boy, do the teethe hold the case together. Perhaps the best way is to use two very-very sharp screwdrivers, insert one between the plastic and the metal and then lift up a bit and then insert the second screwdriver a little further on and lift up again, hopefully the plastic is lifted enough. The procedure is used all the way around the MacMini, one screwdriver after the other, until the two parts pop open.

Replacing the RAM Bank

The MacMini PowerPC G4 uses a single RAM bank rated at  and the motherboard can address a maximum of

and the motherboard can address a maximum of  of RAM. Maxing out the RAM is very very cheap to do, especially since modern computers use way more than

of RAM. Maxing out the RAM is very very cheap to do, especially since modern computers use way more than  of RAM, such that the modules found are fairly cheap. the RAM module must be a PC RAM module, unlike the followup MacMinis that use laptop RAM.

of RAM, such that the modules found are fairly cheap. the RAM module must be a PC RAM module, unlike the followup MacMinis that use laptop RAM.

With the case removed, the following is an image on the side of the MacMini showing the RAM slot with the RAM stick removed.

Here are the complete specifications of the accepted RAM module: 1GB 333MHz 2.5V 184-Pin DDR-PC-2700 Desktop Computer Memory with the following module being an example module found on Amazon.

For 2025, this is a very low-cost investment with large rewards relative to the machine.

Replacing the Hard-Drive

Contrary to the RAM, replacing the hard-drive is almost obligatory because by replacing the hard-drive and aside from the DVD drive, the machine becomes mechanical-free thereby eliminating a huge vector of potential damage to the machine. Typically, dropping electronics on the floor does not damage them and quite on the contrary, they are actually extremely shock resistant but spinning hard-drives are the complete reverse, extremely susceptible to mechanical shock.

The MacMini has a 2.5" IDE socket and fortunately adapters exist that can plug into the IDE socket and then connect to an SSD. Of course, the SSD will have a speed much higher than the IDE such that the IDE will be the bottleneck however the gains will be in terms of longevity and quality of storage. Ironically enough, even though SSDs have a fixed number of possible write-cycles compared to a spinning mechanical disk that does not have any fixed lifespan, the mechanical spinning disk will die much sooner than the SSD, simply due to its mechanical properties that are placed under strain over time.

Here are the possible adapter variants:

- IDE converter to:

- MSATA SSD, an SSD drive used in micro-computers, similar to an NVME drive but much smaller,

- MMC, MMCs are CompactFlash cards, conventionally used in professional photography, like Cannon, Kodak, etc, and they are fairly robust, some of these cards also being used in industrial equipment with "enterprise" variants existing with very long life-cycles,

- microSD, the small cards used in every (modern, heh) phone,

- SATA, these adapters are tricky because they require extra power and the MacMini by default does not have a power connector, the main reason being that the IDE port works at

whereas SATA needs

whereas SATA needs  and the main feeling of users that have picked this option for retro-computers is that the adapters are typically of very poor quality.

and the main feeling of users that have picked this option for retro-computers is that the adapters are typically of very poor quality.

There is a certain cost-to-value ratio that should be considered, in spite of the technology. The cheapest variant when factoring in coin-per-gigabyte of storage is by far the IDE to SATA. A 1TB SATA drive from a known brand can be at no more than USD 70 whereas a 1Tb MSATA SSD is double the price at USD 140. Perhaps the worst of all variants is the microSD, mainly because they are not meant in any way to constitute a storage device for a computer (ie: fast file transfers, overwrites and frequent reads) and also because they are very expensive if large storage such as 1TB is sought after. The MMC and Compact Flash variants are not too bad, but CF has typically a low transport speed, CF is an older technology and similar to the microSD it will also be difficult to find a CF with a large storage capacity.

We went the MSATA SSD route, it is pricey but also fairly modern and will more than likely last well beyond the lifetime of the MacMini itself. The following image is the IDE to mSATA adapter that was used.

It costs about 10 bucks and it is one of these ironed technologies that is not in a state of flux and lasts forever. The image does not do much justice to the actual size of it, in spite of the IDE pin header being displayed but it is about half the size of a human palm.

The SSD has to be bought separately and it is much more expensive. With SSDs, the more storage space, the better, even if it is not going to be fully occupied and that is mainly due to the usage patterns of write-cycles. In our particular case, the storage was actually scaled to the sum-total software size of the Commodore Amiga, in order to make sure that we would fit every single Amiga software ever produced (that people also managed to preserve) onto one single SSD drive. For us the machine will just be a complete all-in-all Amiga replacement (in order to carry on maintaining our published Amiga software).

Overclock

MacMini PowerPC G4 variants that are around are typically clocked at  ,

,  ,

,  and

and  although these variants are similar and have similar tolerances such that they can be overclocked considerably. This was an era before highly-specific implementations of motherboards and PCBs such that the MacMini has "jumpers" on the motherboard that allow overclocking and downclocking the MacMini. Typically, these would have been used during Quality Control (QC) where the machines would have been stress tested at their projected speeds and then downclocked if necessary in order to keep the machine stable.

although these variants are similar and have similar tolerances such that they can be overclocked considerably. This was an era before highly-specific implementations of motherboards and PCBs such that the MacMini has "jumpers" on the motherboard that allow overclocking and downclocking the MacMini. Typically, these would have been used during Quality Control (QC) where the machines would have been stress tested at their projected speeds and then downclocked if necessary in order to keep the machine stable.

Unfortunately for this one, the MacMini has to be completely disassembled. The DVD and HDD caddy on top is removed by unscrewing three screws that hold the assembly in place on top of the motherboard. After that the whole assembly is set aside and the motherboard is lifted and then pulled out from the connector sockets.

Aside from the plastic jaws that could just be replaced by four simple screws, the design is pretty good, kept very simple with very few moving parts or parts that would require very special tools such that disassembling the MacMini into its most basic components can be performed with just a screw-driver. Furthermore, it is clear that this is the era post-Commodore, all but two capacitors (and those are for the audio) are tantalum capacitors without any lifespan, the PCB seems very clean and well-thought out and everything is easily accessible. Quality.

The solder points that are very close together at the bottom of the image are the solder points corresponding to the RAM socket and on the opposite end are the "jumpers" that must be used to overclock the machine.

"Jumpers" is written with sneer-quotes because compared to the older model, Apple decided that this newer model does not need real "mechanical jumpers" but that the "jumpering" would consist in solder pads and resistors. Unfortunately, soldering will be required for this one and judging by the size of the resistors, it looks like this job will have to be performed under a microscope.

The "resistors", again, mind the sneer-quotes, are what's called  resistors because they are nothing but equivalent to a wire without any resistance. It's just that in mass-production there is no "very tiny wire" but the machines that assemble these computers do understand a surface-mount resistor, such that instead of creating a different machine, a resistor with no resistance is used instead.

resistors because they are nothing but equivalent to a wire without any resistance. It's just that in mass-production there is no "very tiny wire" but the machines that assemble these computers do understand a surface-mount resistor, such that instead of creating a different machine, a resistor with no resistance is used instead.

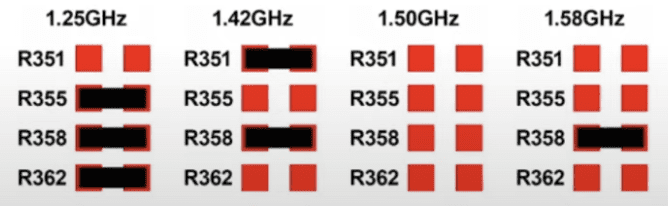

From top to bottom, the resistors read R351, R355, R358 and R362 and the text that marks them is written on the PCB as observed in the former image. By floating or connecting pairs of solder-pads in various combinations, different clock multipliers can be achieved that will multiply with the base clock and hence set the CPU speed of the MacMini. One image that comes up ever more often on the Internet that depicts CPU speed by jumper configuration is the following.

Now, it depend what CPU set is to be set. The MacMini model that we ended up with is a  machine and it had the second jumper configuration. It as decided to remove

machine and it had the second jumper configuration. It as decided to remove R351 in order to bump to up a speed of  . Technically speaking, it is possible to go higher but it is a good idea to change the thermal paste as well as thoroughly clean the MacMini before doing so. Various users report that

. Technically speaking, it is possible to go higher but it is a good idea to change the thermal paste as well as thoroughly clean the MacMini before doing so. Various users report that  seems stable but more than that makes the MacMini create graphics artifacts or glitch the graphics such that

seems stable but more than that makes the MacMini create graphics artifacts or glitch the graphics such that  seems the best bump.

seems the best bump.

The procedure to remove R351 is done under the microscope by watching the microscope screen directly due to the extremely small size of the resistors. First, a ball of flux is added and then melted with some solder to ensure that the area around the resistor and the resistor itself is wet. the technique will be to heat up the resistor a little and at the same time start to add solder in order to obtain a solder bag (we like calling it a bag, but it is a ball) that will be dragged with the tip on top of the resistor and made to surround the resistor. Now, due to fluid dynamics, this ball / bag of solder is connected to the tip of the solder gun and also wrapped around the resistor such that the heat from the solder gun is transferred to the ball and onto the resistor. Waiting a little like this in this position makes the solder from the ball warm up the resistor and the pads that it is connected to until the resistor can just be (bagged) dragged away with just the tip. Using this technique is perhaps the best way to de-solder a surface-mount component when the PCB or motherboard is more important than the component itself. The reason for that is that the solder gun typically provides just a tip with the tip of the gun being the hottest and capable to burn the PCB but by transferring the heat through a ball of solder, the heat is distributed across the entire surface of the component and also the solder pads. If one were to attempt to remove this resistor just by poking it with the solder tip, either the motherboard would end up burned out or the solder pad itself might give way and break off or in the best case it would take a whole of forever to remove.

The video above shows the abbreviated process of removing the surface-mount resistor and hence overclocking the MacMini as it was formerly described. Note that some modders prefer to keep the resistor but bear in mind that the resistor itself is an industrial hack to not make a separate machine for jumpers such that it is a completely worthless and meaningless resistor that, in case a rollback is desired, could just as well be replaced by a small or tiny copper wire and will work just the same. However, in our opinion, messing around with the clock speed is unnecessary and redundant given power management - it has already been established what this machine will be used for so we leave it at the speed that it will be used for.

Updating OpenFirmware to Account for Modified Clockspeed

OpenFirmware is a very cool BIOS alternative that allows manipulating the hardware very early on. Unfortunately, after the MacMini is overclocked to  , there is no OpenFirmware definition for such a speed because there is no MacMini produced that ever had such a speed, such that if one were to boot into OSX, the "About this Mac" screen would claim that the CPU is running at

, there is no OpenFirmware definition for such a speed because there is no MacMini produced that ever had such a speed, such that if one were to boot into OSX, the "About this Mac" screen would claim that the CPU is running at  . Some users suggest that this is due to energy management after the overclock setting the CPU to the lowest possible speed but in reality the wrong

. Some users suggest that this is due to energy management after the overclock setting the CPU to the lowest possible speed but in reality the wrong  speed is due to no definition for this clock speed existing in the BIOS / OpenFirmware of the MacMini.

speed is due to no definition for this clock speed existing in the BIOS / OpenFirmware of the MacMini.

This issue does not seem that vital and most of the time the "display figure" is not too important because the CPU is forcibly overclocked to  anyway, however one must imagine the flow of logic for many software packages that might have made the software take decisions based on the information contained within the OpenFirmware BIOS. Of course, there might be other ways to read the CPU speed but a software package might rely on the value from OpenFirmware in order to, say, adjust the graphics quality of their program and will hence opt for a very bad quality corresponding to

anyway, however one must imagine the flow of logic for many software packages that might have made the software take decisions based on the information contained within the OpenFirmware BIOS. Of course, there might be other ways to read the CPU speed but a software package might rely on the value from OpenFirmware in order to, say, adjust the graphics quality of their program and will hence opt for a very bad quality corresponding to  relative to the real speed that is now

relative to the real speed that is now  . In fact, to be fair, in case it would not have been possible to change OpenFirmware, the overclock should have rather been reversed (and even trivially, the difference from

. In fact, to be fair, in case it would not have been possible to change OpenFirmware, the overclock should have rather been reversed (and even trivially, the difference from  which is the original value to

which is the original value to  is far greater than from

is far greater than from  to

to  ).

).

In order to update OpenFirmware, the following operations have to be carried out:

- shut down the Mac Mini,

- hold down Windows(or Command key on an original Apple keyboard)+Alt+O+F while booting (a trick here is to actually mash the combination instead of holding the keys down; this is due to not having an original Apple keyboard such that legacy keyboards are initialized later in the boot process hence the window of opportunity to register the key-combo request to enter OpenFirmware is lost by the time that the keyboard is initialized)

When prompted for commands at the OpenFirmware prompts, the following commands should be used:

nvedit dev / 9eb18ef encode-int " clock-frequency" property dev /cpus dev PowerPC,G4@0 5e2ce2fd encode-int " clock-frequency" property 9eb18ef encode-int " bus-frequency" property 5e1da0c0 encode-int " rounded-clock-frequency" property 5e178682 encode-int " recalced-clock-frequency" property 27ac63b encode-int " timebase-frequency" property dev l2-cache 5e2ce2fd encode-int " clock-frequency" property dev /

as provided by DanielNTX on www.mac-forums.com and then press Ctrl+C followed by:

nvstore setenv use-nvramrc? true reset-all

in order to store the changes and reboot the machine.

In essence, this sequence will update OpenFirmware and set the clock speed to computed values corresponding to the  overclock. They will update the CPU clock registry, the bus frequency, provided some rounded frequencies and also update the L2 cache speed reporting. Note that this is extremely arduous to type out and the NVRAM editor

overclock. They will update the CPU clock registry, the bus frequency, provided some rounded frequencies and also update the L2 cache speed reporting. Note that this is extremely arduous to type out and the NVRAM editor nvedit is just a line-editor such that after one line is entered it is not displayed anymore. In case the operation fails, the MacMini should be booted back into OpenFirmware and then the firmware has to actually be reset by typing out the following commands:

reset-nvram set-defaults reset-all

that will reset everything to the defaults in order to be able to try again.

When no mistakes are made, the MacMini should boot into MacOS again and this time the "About this Mac" window should display the correct  frequency just like the image below.

frequency just like the image below.

For the contact, copyright, license, warranty and privacy terms for the usage of this website please see the contact, license, privacy, copyright.