Table of Contents

About

UPS batteries can be considered highly specialized equipment by contrast to car batteries that are more widespread due to the automotive industry. By consequence, UPS batteries tend to cost more, especially when buying originals and not aftermarket replacements. Moreover, given the appropriate input voltage, the battery ratings are rather low, even for medium range UPSes such that it makes no difference if the batteries are replaced by higher rating equivalents. One after-market trick that seems viable is to purchase second-hand UPSes, preferably without batteries and hook up the UPS to car batteries.

This project will retrofit an SC1000i APC UPS with two low-cost car batteries, costing roughly the same amount of money as new batteries but also doubling the runtime due to the high capacity batteries for cars. The SC1000i APC UPS in particular, contains two  batteries that are connected in series in order to deliver

batteries that are connected in series in order to deliver  at about

at about  . By contrast the batteries will be replaced with two

. By contrast the batteries will be replaced with two  car batteries, connected in series and with a rating of

car batteries, connected in series and with a rating of  . Since the batteries will be connected in series, there will be no rating benefits over using a single car battery except for reducing the losses if a voltage upscaler would have to be used to match

. Since the batteries will be connected in series, there will be no rating benefits over using a single car battery except for reducing the losses if a voltage upscaler would have to be used to match  .

.

Price-Check

Unfortunately, UPSes are horribly underestimated devices when it comes to price vs. quality: the UPS itself, meaning the circuitry and the casing will, for sure, outlast the batteries. It is even questionable whether this is an unfortunate side-effect of the market or even intentional by design: at some point, the UPS producer will terminate the model line with an end-of-life statement and shortly thereafter, only aftermarket batteries will be available from third-party sellers that will maintain the same prices or even worse, will crank up the prices claiming scarcity. This will eventually force the user to abandon a fully-functioning UPS and to purchase a brand new UPS that has relatively speaking the same essential features with, perhaps, some little extra bling sprinkled on top.

Taking the case of the APC SC1000i UPS, the product is considered EOL and only aftermarket batteries are available from third-party sellers - even Amazon does not sell them anymore. The SC1000i takes just two  and

and  batteries in series that can be replaced for about

batteries in series that can be replaced for about  (USD52). The original batteries are said to have a lifespan between 3 to 5 years which greatly depends on the actual line quality depending on the location where the UPSes are used - if the line quality is bad, either the voltage fluctuates, power outages abound and so on, then the UPS will do its best to provide quality output and will have to switch more frequently to the batteries in order to compensate for the incompetence.

(USD52). The original batteries are said to have a lifespan between 3 to 5 years which greatly depends on the actual line quality depending on the location where the UPSes are used - if the line quality is bad, either the voltage fluctuates, power outages abound and so on, then the UPS will do its best to provide quality output and will have to switch more frequently to the batteries in order to compensate for the incompetence.

Furthermore, given that the batteries are connected in series, the total power that the battery will be capable of will be about  yielding about USD3.36 per Watt. Contrasted with even the cheapest car batteries with a price of USD78 (such as the ones used for this project) with a power output

yielding about USD3.36 per Watt. Contrasted with even the cheapest car batteries with a price of USD78 (such as the ones used for this project) with a power output  yielding about USD13.23 per Watt, using car batteries seems to be right about 10 times cheaper! Even factoring in the mean time to failure, that in a head-on comparison, is similar between car batteries and UPS batteries (2-5 years) one would have to take into account that car batteries are meant to be almost completely depleted after car ignition yet that usage pattern is, given properly configured power mitigations (ie: UPS commutes to battery, computer shuts down, then the UPS shuts down too and everything restarts when the power is back up), never to be observed when it comes to computers.

yielding about USD13.23 per Watt, using car batteries seems to be right about 10 times cheaper! Even factoring in the mean time to failure, that in a head-on comparison, is similar between car batteries and UPS batteries (2-5 years) one would have to take into account that car batteries are meant to be almost completely depleted after car ignition yet that usage pattern is, given properly configured power mitigations (ie: UPS commutes to battery, computer shuts down, then the UPS shuts down too and everything restarts when the power is back up), never to be observed when it comes to computers.

To summarize: purchase bare-metal UPSes with the various desired electronic features (connectivity, interfaces, yadda) but without batteries and substitute the batteries by car batteries for a much better bang for the buck.

Preliminaries

One of the first things to check what voltage is required by the UPS - this can be done on Linux, for example, by using the nut software package or the apcupsd package. On Windows, the official APC UPS PowerChute software can be installed instead. On Linux, issuing:

upsc UPS

where:

UPSis the UPS name defined in the nut configuration files

should yield the battery details:

battery.alarm.threshold: 0 battery.charge: 100.0 battery.charge.restart: 00 battery.date: 10/15/06 battery.runtime: 2000 battery.runtime.low: 120 battery.voltage: 26.60 battery.voltage.nominal: 024

The battery voltage is detected to be  which is indicative of a

which is indicative of a  UPS and is also confirmed by the

UPS and is also confirmed by the battery.voltage.nominal parameter.

Requirements

- a container to fit both car batteries - this should be sized to fit the batteries next to each other and the size depends on the types of batteries used; the main reason for using an enclosure is to try and contain any fumes or minimize the damage in case of a fire - furthermore, the box will be cut in order to fit a kettle plug.

- kettle plugs - kettle plugs are going to be used to connect the batteries to the UPS on both ends mainly due to the rigidity of the connectors and the size of the contacts,

- wires - car batteries are usually associated with very thick wires, the reason therefore is the high amperage required to start the car initially; however, in this case, no initial high amperage is required and commuting to the batteries will not require that many amperes; one good and cheap solution is to use a standard plug extender and strip the wires bare - two wires are going to be used and the grounding can be left floating,

- measuring equipment: voltmeter and ohmmeter - due to the high currents it is imperative to check and double check that all the connections are sound,

- dremel, solder and the rest of the required DIY equipment.

Overall Wiring Diagram

The wiring is rather trivial and requires that the two batteries be connected in series - some care must be given to not produce a short since car batteries are designed to quickly discharge when a load is connected:

to kettle plug to kettle plug ^ - + ^ | +---+ | | | | | | - + | | - + | +-----------+ +-----------+ | | | | | Battery | | Battery | | | | | +-----------+ +-----------+

Box Wiring

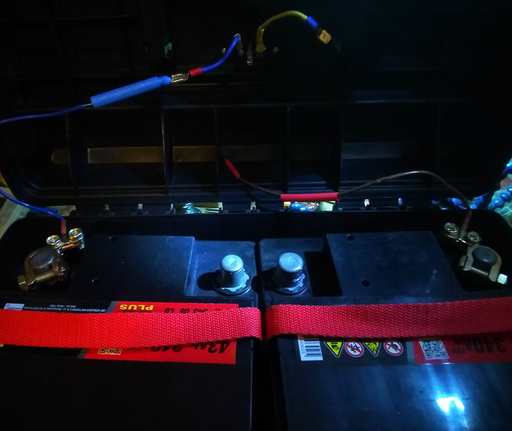

The box is modified to fit a kettle plug, the innermost terminals are connected to form the serial circuit and the batteries are placed inside the case with leads drawn from both outermost terminals to the plug on the case.

One extra advantage for using a toolbox is that the case can be closed shut and, if necessary, could even be altered to be air tight - nevertheless, the original batteries for the UPS are also lead-acid batteries such that it should not make much of a difference in case the car batteries chosen are sealed.

UPS Connector Wiring

With the container wired and the batteries placed inside, the next step is to extract the battery cable from the UPS and rewire it to fit a male kettle plug. The wiring depends on the UPS, but in the case of the APC SC1000i, the battery wiring contains three leads, two of which are just shortened and carry  .

.

APC UPS SC1000i

connector

+----------------+

| 24V | --->

+----------------+

| 24V | ---> to UPS

+----------------+

| GND | --->

+----------------+

In case the connector does not lock, it is important to check which of the pins correspond to ground or voltage since some UPSes do not contain a protection circuit. In fact, the SC1000i contains a warning on the UPS connector plug itself stating that the polarity is not checked by the UPS such that extra care must be given by the user to properly connect the batteries the right way round.

On the other end, the UPS mask is removed and a sizeable hole drilled into the casing in order to fit a kettle plug.

Everything is then assembled back together and the batteries are connected to the APC UPS - if there is enough space, the battery pack can also then be conveniently placed inside a rack; preferably on the bottom of the rack to reduce the amount of heat around the batteries.

Software

With the battery connected, the upsc command can be issued on Linux in order to check that the battery has been properly installed:

battery.alarm.threshold: 0 battery.charge: 100.0 battery.charge.restart: 00 battery.date: 10/15/20 battery.runtime: 180 battery.runtime.low: 120 battery.voltage: 26.60 battery.voltage.nominal: 024

The NUT CGI script can also be installed in order to issue commands or see the APC UPS statistics. One feature of the CGI script is that a power outage simulation command can be issued via the interface, at which point the UPS should commute to the battery for a little while.

However, a better test, once everything is connected, is to simply disconnect the mains power from the UPS and check that the UPS properly switches to the batteries and runs properly - perhaps even, in combination with monitoring the UPS statistics to check that the batteries are properly discharging. When the mains are connected to the UPS again, the statistics should be monitored in order to check that the batteries are properly charging. If necessary, a full discharge-charge cycle can be run as a complete test.

Issues and Further Developments

- the SC1000i APC UPS did not recognize the batteries and shows that the batteries must be replaced - however, the UPS has no problems commuting to the batteries once the mains are disconnected and runs seemingly without issue. Furthermore, the UPS charges the batteries when monitoring the statistics such that the only downside seems to be the extra bling of an additional red LED that will not go away.

- if the UPS fails to recharge the batteries, then a car battery charger can be connected in parallel to the batteries - in this case, the charger would have to output

- many UPSes tend to have a parallel-serial circuit where an amount of batteries are used to achieve the voltage required by the UPS whilst the additional batteries are coupled between each-other in series but connect to the rest of the batteries in parallel in order to deliver a higher capacity. If need be, the same can be achieved with car batteries and the capacity can be extended to whatever is necessary. Note that an UPS might have a built-in fuse that may prevent exceeding a certain amperage threshold such that the fuse itself may have to be replaced in case the UPS is to be extended further.

- sealed batteries have the advertised advantage of not requiring maintenance (this usually means adding water to the elements from time to time) but as it turns out the batteries still need some maintenance and adding additional water to compensate for evaporation is a good thing - these "maintainance-free" batteries have a small casing on top with deeply nested holes for screws that, once removed, will reveal the small maintenance hatches where water can be added

- both UPS batteries and car batteries are lead-acid batteries such that the health and safety concerns should be more or less the same - the only difference would be that car batteries are much larger and hence might produce a larger quantities of fumes. The main concern is to mitigate hydrogen and oxygen emanations from the batteries that might, once released, recombine into sulfuric acid leading potentially to something called "blue smoke". If necessary, the container can be made air-tight, fitted with a plastic aquarium air tube and the tube can then be moved outside the room.

For the contact, copyright, license, warranty and privacy terms for the usage of this website please see the contact, license, privacy, copyright.